The A320’s oxygen system is thoroughly outlined in the Flight Crew Operating Manual (FCOM), providing technical and operational details critical for crew safety and passenger support in emergencies. Below is a detailed breakdown of the A320’s oxygen system, adhering closely to the FCOM structure, which includes both the crew oxygen system and the passenger oxygen system.

Crew Oxygen System

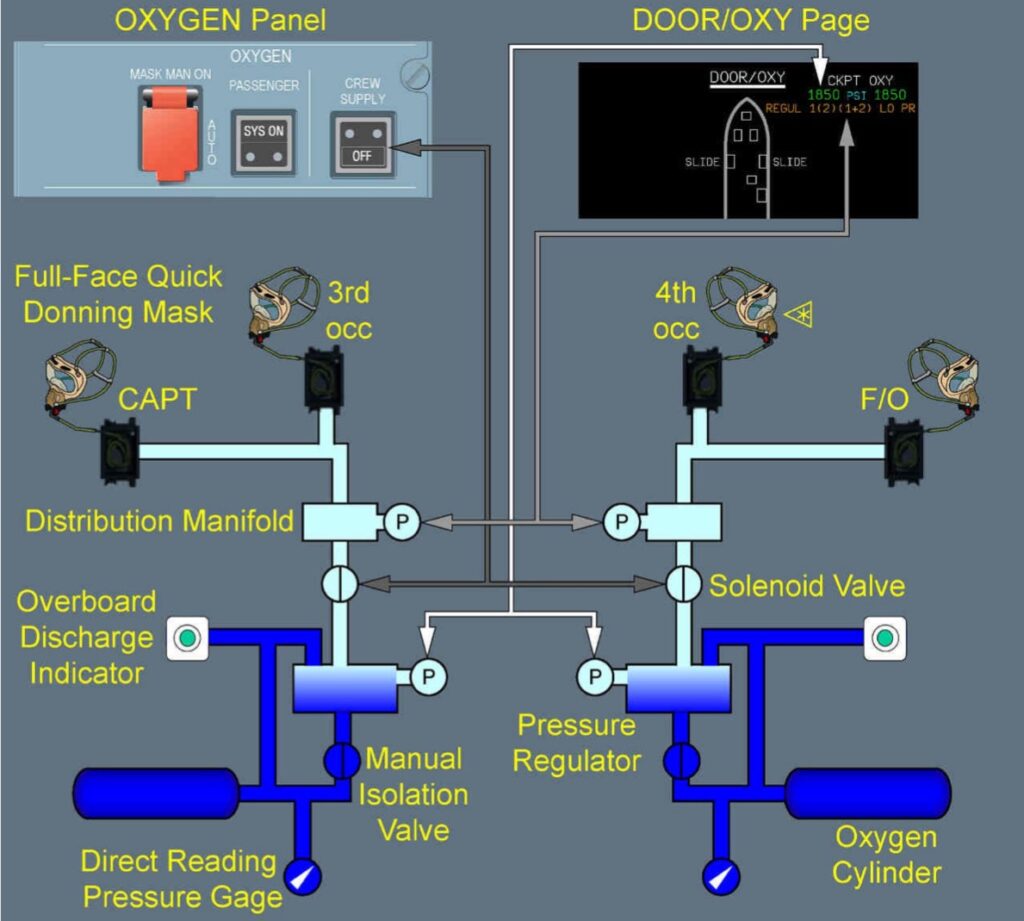

The crew oxygen system is intended to supply the flight deck crew with a reliable oxygen source in emergencies, such as depressurization or smoke in the cockpit. This system consists of several components, as detailed in the FCOM:

Oxygen Storage

High-Pressure Cylinder: Oxygen for the flight crew is stored in a high-pressure cylinder, generally located in the avionics compartment. This cylinder typically holds oxygen at around 1,850 psi when fully charged. It is designed to supply adequate oxygen for all flight deck crew members based on regulatory requirements for emergency descent and landing.

Pressure Regulation: Oxygen stored at high pressure is regulated down to a manageable pressure level for use in the cockpit. The reduction mechanism ensures that, regardless of the cylinder’s initial pressure, the oxygen delivered to the masks is at a comfortable and usable pressure.

Pressure Indicator and Warning: The cylinder pressure can be monitored directly on the OXY page on the ECAM (Electronic Centralized Aircraft Monitor) and the indicator on the crew oxygen panel. The system provides a low-pressure alert if oxygen falls below the minimum required levels, ensuring that crew members are aware of any potential shortages before an emergency occurs.

Crew Oxygen Masks

Quick-Donning Masks: Each pilot seat is equipped with a quick-donning oxygen mask, designed to be worn within five seconds in an emergency. The masks have multiple oxygen flow modes, which can be adjusted according to the situation:

Normal Mode: Provides a mix of ambient cabin air and oxygen, conserving the oxygen supply while maintaining safe oxygenation at lower altitudes.

100% Oxygen Mode: Supplies pure oxygen to prevent any cabin contaminants from entering the mask; this is particularly useful in smoke or contaminated air situations.

Emergency Mode (Positive Pressure): In emergency mode, the mask provides a constant positive flow of oxygen. This setting maintains a positive pressure within the mask, preventing contaminants or smoke from seeping in.

Microphone Integration: The oxygen masks are integrated with microphones, allowing the crew to continue communicating via the aircraft’s communication systems without having to remove the masks.

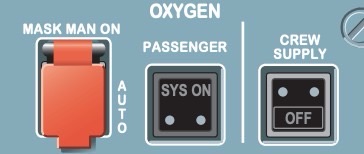

Control and Test Functions

Crew Oxygen Control Panel: The oxygen control panel for the crew is located on the overhead panel, allowing for the monitoring of system status and cylinder pressure.

Built-In Test Features: The FCOM specifies a test button on the oxygen control panel that allows the crew to check mask operation before departure. This feature helps ensure that each mask is functioning correctly and that oxygen will flow as expected in an emergency.

Passenger Oxygen System

The passenger oxygen system operates differently from the crew’s system, using chemical oxygen generators instead of high-pressure cylinders. This design reduces weight and complexity while ensuring that oxygen is available for passengers during depressurization.

Chemical Oxygen Generators

Location and Function: Chemical oxygen generators are installed above passenger seating areas, with one generator typically serving a set number of seats in a given row. These generators provide oxygen through a chemical reaction initiated when a passenger pulls down on an oxygen mask.

Activation Process: When cabin altitude reaches approximately 14,000 feet, the passenger oxygen system automatically activates, and oxygen masks deploy from overhead compartments. Pulling the mask downward triggers a pin that ignites the chemical generator, initiating a reaction that produces oxygen.

Duration: Each generator supplies oxygen for approximately 12 to 15 minutes, providing sufficient time for the aircraft to descend to a lower, breathable altitude where passengers can rely on ambient air.

Passenger Oxygen Masks

Deployment: Passenger masks are stored in compartments above each seat and are deployed automatically when a depressurization event occurs. The FCOM specifies that the system will also deploy masks manually if triggered by the crew via the Passenger Oxygen Control Button on the overhead panel.

Instructions for Use: Passengers are instructed to pull the mask down toward them, which initiates oxygen flow. The system is simple and does not require additional passenger action to start the oxygen generation process.

Mask Design: The masks are fitted with elastic bands to fit securely on passengers’ faces. In addition, a one-way valve ensures that oxygen flows consistently while preventing exhaled air from re-entering the mask.

Monitoring and Control

The A320’s oxygen system includes comprehensive monitoring and control features, enabling the crew to manage and troubleshoot both crew and passenger oxygen systems effectively.

ECAM Indications

- The ECAM (Electronic Centralized Aircraft Monitoring) system provides real-time information on the oxygen system’s status, including cylinder pressure for the crew system and deployment status for the passenger system. This monitoring helps alert the crew to any malfunctions or low-pressure situations that require intervention.

Warnings and Alarms: If the cabin altitude exceeds 14,000 feet or if there is a fault in the oxygen system, the ECAM generates an alert, ensuring the crew is immediately aware of the situation.

Emergency Oxygen Control Panel

- The emergency oxygen panel, located in the cockpit, allows the crew to manually deploy passenger oxygen masks if necessary. The Passenger Oxygen Control Button overrides the automatic deployment function, ensuring the system can still be activated in case of a malfunction.

Preflight Checks: The FCOM outlines required preflight checks for the crew oxygen system, such as verifying adequate oxygen cylinder pressure and testing the mask operation. The passenger oxygen system, although automatic, includes maintenance checks to ensure that each generator and mask compartment is ready for deployment if needed.

Safety Protocols and Limitations

Duration Awareness: The limited duration of passenger oxygen, typically lasting only 12-15 minutes, necessitates a prompt descent by the crew in a depressurization emergency. The crew must plan to reach a safe altitude before the passenger oxygen supply is depleted.

Cabin Altitude Management: To avoid unnecessary activation, the pressurization system in the A320 is designed to maintain a safe cabin altitude even at high cruising altitudes. Only in extreme depressurization scenarios does the system automatically deploy passenger oxygen.

Summary

The A320 oxygen system, as described in the FCOM, ensures that both the crew and passengers have access to emergency oxygen in case of depressurization. The system uses a high-pressure cylinder for the crew and chemical oxygen generators for passengers, each with unique activation processes and safety features. Monitoring through the ECAM system and controls on the overhead panel give the crew full control over oxygen deployment and supply levels. This detailed redundancy and built-in safety checks ensure that the oxygen system remains reliable and effective under a range of emergency conditions.

For all aviation-related guidance (DGCA ground classes, pilot training, cabin crew training)

Contact us https://contrail.in/

phone numbers +91 78457 69399