Following the recent emergency airworthiness directive concerning the Airbus A320 fleet, one specific component has emerged as a focal point: the Elevator Aileron Computers, commonly referred to as ELACs.

Manufactured by Thales, the ELACs were the systems that initiated the uncommanded pitch-down on JetBlue Flight 1230 in October. Consequently, an emergency airworthiness directive was issued for the Airbus A320 fleet, and it is certain that this issue will be a topic of discussion within the industry for some time.

In this article, we will examine what the ELACs are and why they hold such significance.

Why ELACs are crucial for A320 pitch and roll control

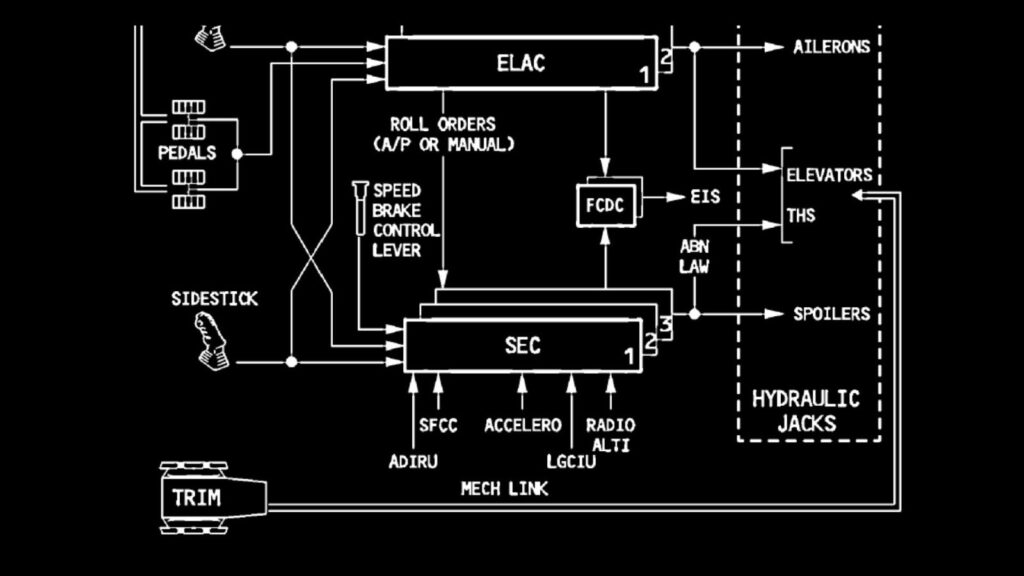

Seven flight control computers process inputs from both the pilot and the autopilot in accordance with Airbus’s fly-by-wire flight control laws. This system includes two ELACs, three SECs (Spoiler and Elevator Computers), and two FACs (Flight Augmentation Computers).

The ELACs consist of a pair of computers that essentially serve as the aircraft’s brain for managing its pitch and roll axes. These devices take the commands from the pilot or autopilot and translate them into precise, accurate movements of the elevators and ailerons.

The ELACs also gather data from seven other aircraft systems, including the three ADIRUs (Air Data Inertial Reference Units), FMGC (Flight Management Guidance Computer), and radio altimeters.

For A320 pilots, the ELACs are among the critical systems that ensure the flight experience remains stable, controlled, and characteristically “Airbus”.

So, what exactly is an ELAC?

As previously stated, ELAC stands for Elevator Aileron Computer, and the A320 is equipped with two units – ELAC 1 and ELAC 2.

Together, they constitute a fundamental element of the fly-by-wire system. Rather than relying on traditional pulleys and cables, all commands are transmitted through electrical signals. The pilot manipulates the sidestick, the ELACs interpret the input, and the aircraft responds accordingly.

Interestingly, even in the event of a failure of both ELACs, the aircraft will still be operable – although it will lose some flight control protections and the autopilot function.

What the ELAC system actually performs

The ELACs are accountable for multiple functions:

Elevator control

The elevators, located on the horizontal stabilizer, are the control surfaces that enable the aircraft to pitch up or down. When the pilot pulls or pushes on the sidestick, or when the autopilot instructs a pitch adjustment, the ELACs convert those inputs into specific elevator deflections to achieve the desired pitch attitude.

Aileron control

At the wingtips, the ailerons regulate the aircraft’s roll – its ability to bank left or right. The ELACs interpret the roll inputs from the pilot or autopilot and direct the ailerons to establish the intended bank angle.

Enforcing flight control laws

This aspect is crucial to Airbus’ design philosophy. The ELACs play a vital role in upholding the embedded control laws – the regulations that dictate how the aircraft reacts to inputs from both the pilot and the autopilot, as well as how it safeguards itself against overspeed or unacceptable angles of attack.

These safeguards ensure that the aircraft remains within safe operating parameters, even if a pilot oversteers or faces severe turbulence.

Fault detection and redundancy

Airbus engineers its systems with the understanding that failures may occur, and the ELACs are included in this consideration. Both computers continuously monitor their own functionality and the control surfaces they oversee.

If one ELAC encounters a problem, the other effortlessly takes over. Any irregularities are reported to the flight deck, allowing the crew to respond appropriately via the ECAM (Electronic Centralised Aircraft Monitoring).

What’s the difference between ELAC 1 and ELAC 2?

Despite being identical in design, they perform distinct functions:

ELAC 1: Primarily responsible for the ailerons and certain elevator functions, particularly those powered by the blue hydraulic system.

ELAC 2: Manages the elevators and the Trimmable Horizontal Stabiliser (THS), utilizing the green and yellow hydraulic systems.

If the A320’s fly-by-wire configuration serves as its nervous system, the ELACs can be likened to the brain’s function in ensuring pitch and roll are smooth, predictable, and secure. Given the recent solar radiation concerns impacting A320s, these two small computers are likely to receive increased scrutiny in the upcoming weeks and months.

How a fault with the ELACs caused a JetBlue pitch down

On 30 October 2025, JetBlue Airways Flight 1230, operating an Airbus A320 with the registration N605JB, took off from Cancún, Mexico (CUN) en route to Newark, New Jersey (EWR).

Approximately two hours into the flight, at flight-level 350 (around 36,000 ft), the aircraft experienced a sudden uncommanded nose-down pitch that lasted for 4–5 seconds, prompting the crew to declare an emergency and divert to Tampa, Florida (TPA).

About 15–20 passengers sustained minor injuries.

Investigators determined that the incident was instigated by a malfunction in the ELAC flight-control computer of the Airbus A320 involved. That particular ELAC unit, equipped with software version L104, reportedly experienced data corruption, a flaw associated with intense solar radiation, which led to erroneous elevator commands being issued without pilot intervention.

The resulting uncommanded pitch-down caused the aircraft to descend rapidly, necessitating an emergency diversion, a situation serious enough that regulators mandated a global directive requiring all affected A320s to undergo software updates or have their ELAC hardware replaced before being allowed to fly again.

Airlines have quickly complied, with Airbus announcing on Monday, 1 December, that only about 100 aircraft are still pending software updates.

For all aviation-related guidance (DGCA ground classes, pilot training, cabin crew training)

Contact us https://contrail.in/

phone numbers +91 78457 69399