The Airbus A320 hydraulic system is a critical part of the aircraft’s operation, providing power to various flight control surfaces, landing gear, brakes, nosewheel steering, and other components. The A320 uses three independent hydraulic systems—Green, Blue, and Yellow—each with its own dedicated power sources to ensure redundancy and reliability. Below is a detailed breakdown of the components, operation, and redundancy features of the A320 hydraulic system.

General Overview

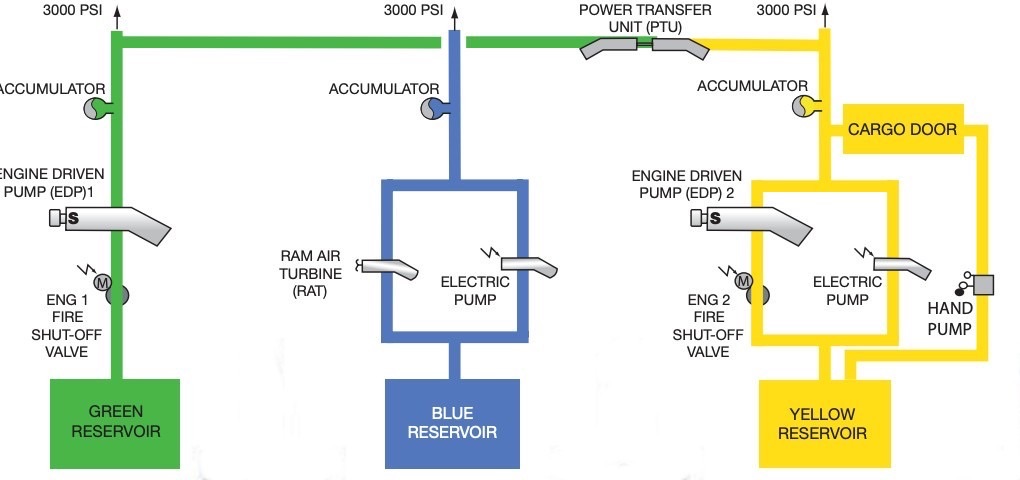

The hydraulic system on the A320 operates at a normal pressure of 3000 psi and powers essential systems. The three independent hydraulic systems (Green, Blue, and Yellow) ensure that if one or even two systems fail, critical systems remain operational through the remaining system(s).

Hydraulic System Components

Each of the three hydraulic systems comprises the following core components:

Reservoir: Stores hydraulic fluid and allows for temperature expansion and contraction.

Pumps: Different systems use different types of pumps (engine-driven, electrical, and manual).

Accumulator: Maintains system pressure and compensates for small pressure fluctuations.

Power Transfer Unit (PTU): Enables transfer of hydraulic power between systems without transferring fluid.

Valves: Control the flow and pressure of the hydraulic fluid.

Cooling System: Keeps the hydraulic fluid temperature within safe operating limits.

Green Hydraulic System

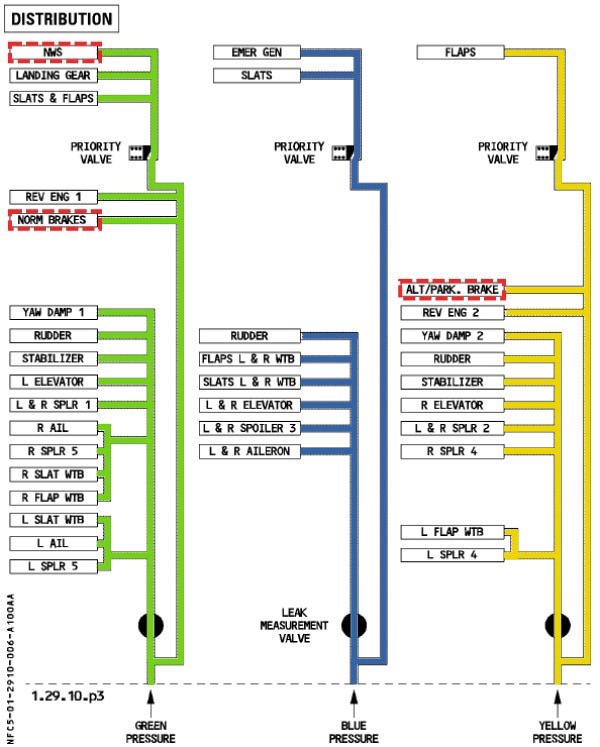

The Green system is primarily powered by an Engine-Driven Pump (EDP), which is connected to Engine 1. It also has a reservoir for fluid storage and an accumulator to smooth pressure fluctuations. This system powers critical functions, including:

- Primary flight controls (elevators, ailerons, rudder, spoilers)

- Landing gear

- Normal braking system

- Some spoilers and slats.

If the Green system fails, other systems (Blue or Yellow) can take over some of its functions, ensuring that critical control surfaces remain functional.

Blue Hydraulic System

The Blue system operates differently as it is powered by an Electric Pump, not tied to either engine. This provides redundancy since the Blue system operates independently of engine power. The Blue system also has its own reservoir and accumulator.

Key systems powered by the Blue hydraulic system include:

- Primary flight controls (elevator, rudder, spoilers)

- Emergency power for some flight control surfaces

In case of a complete electrical failure, the RAT (Ram Air Turbine) can deploy to provide emergency hydraulic pressure to the Blue system. The RAT is a small wind turbine that extends into the airflow, generating hydraulic pressure from the airstream.

Yellow Hydraulic System

The Yellow system is powered by an Engine-Driven Pump (EDP) connected to Engine 2, but it also features a Backup Electric Pump, allowing it to function without the engine running (e.g., during ground operations).

Key functions of the Yellow system include:

- Alternate flight controls (elevator, rudder, ailerons, spoilers)

- Cargo door operation

- Nosewheel steering

- Parking brake

- Alternate braking system

The Yellow Electric Pump allows the crew to operate the system without needing Engine 2, which is useful for ground operations (e.g., operating the cargo doors).

Power Transfer Unit (PTU)

The Power Transfer Unit (PTU) is a unique feature that allows the transfer of hydraulic power between the Green and Yellow systems without mixing hydraulic fluid. The PTU operates automatically if the pressure differential between the Green and Yellow systems exceeds 500 psi.

The PTU ensures that if one of the systems loses its engine-driven pump, the other system can still provide hydraulic pressure to critical systems, ensuring the aircraft remains controllable.

- Example: If Engine 1 (and thus the Green system) fails, the Yellow system can transfer power through the PTU to support systems normally powered by the Green system, such as the landing gear or certain flight controls.

RAT (Ram Air Turbine)

In the event of a complete loss of hydraulic and electrical power, the RAT deploys automatically to provide emergency hydraulic pressure to the Blue system. The RAT is a small wind turbine that generates hydraulic pressure using airspeed. While not designed to power all systems, it ensures that key flight control surfaces remain operational to allow the pilot to safely control the aircraft in an emergency.

Redundancy and Safety Features

The A320 hydraulic system is designed with multiple layers of redundancy:

- Three independent systems (Green, Blue, and Yellow) ensure that failure of one system does not result in a loss of control.

- The PTU allows hydraulic power transfer between the Green and Yellow systems.

- The RAT provides emergency hydraulic power to the Blue system.

- The Yellow Electric Pump provides redundancy and can be used for ground operations or in case of engine failure.

Additionally, the system is equipped with various sensors and alarms that notify the pilots of hydraulic failures or low pressure situations, allowing for quick troubleshooting and corrective actions.

Failure Modes and Emergency Procedures

- If the Green system fails (due to Engine 1 failure or hydraulic loss), the PTU will assist with pressure from the Yellow system.

- If the Yellow system fails (due to Engine 2 failure or hydraulic loss), the PTU will assist with pressure from the Green system.

- In the event of a Blue system failure, the other two systems will still maintain control, and the RAT will deploy if needed for emergency power to the Blue system. Summary

The A320 hydraulic system is highly redundant and designed to ensure that the loss of one or even two systems does not result in the loss of control of the aircraft. The integration of the Green, Blue, and Yellow systems, along with the PTU and RAT, provides multiple backups for critical systems, ensuring the aircraft can be safely controlled in various failure scenarios.

For all aviation-related guidance (DGCA ground classes, pilot training, cabin crew training)

Contact us https://contrail.in/

phone numbers +91 78457 69399

[…] that little windmill that pops out during dual engine failure scenarios in the simulator, but the A320’s RAT serves multiple functions beyond total power loss situations. This small turbine, measuring just […]